M Series Shredder

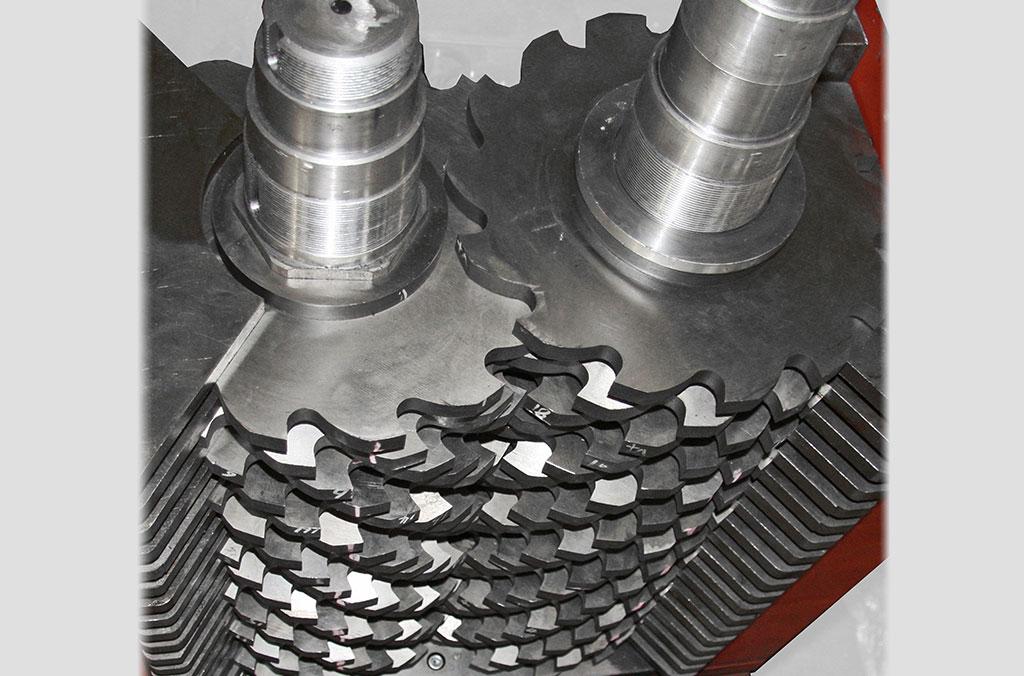

TWIN SHAFT SHREDDER

Low speed, high torque operation minimizes noise and power consumption – whilst achieving high throughput rates. These machines are particularly suited to the size reduction of bulky or voluminous materials which could include contamination such as metals or stones.

Features/Applications

Typical Applications

- Plastics –Mixing Plastics, Plastic Drums or Containers, etc.

- Electronic Scrap – WEEE Directive Materials.

- Tires – Car Tires, Debeaded Truck Tires.

- Wood – Pallets etc.

- Packaging Materials – Cardboard etc.

- Metals – Lead, Aluminum, Copper etc.

- Textiles.

Features

- Slow Speed High Torque Shredding Principle.

- Low Dust and Low Noise Operation.

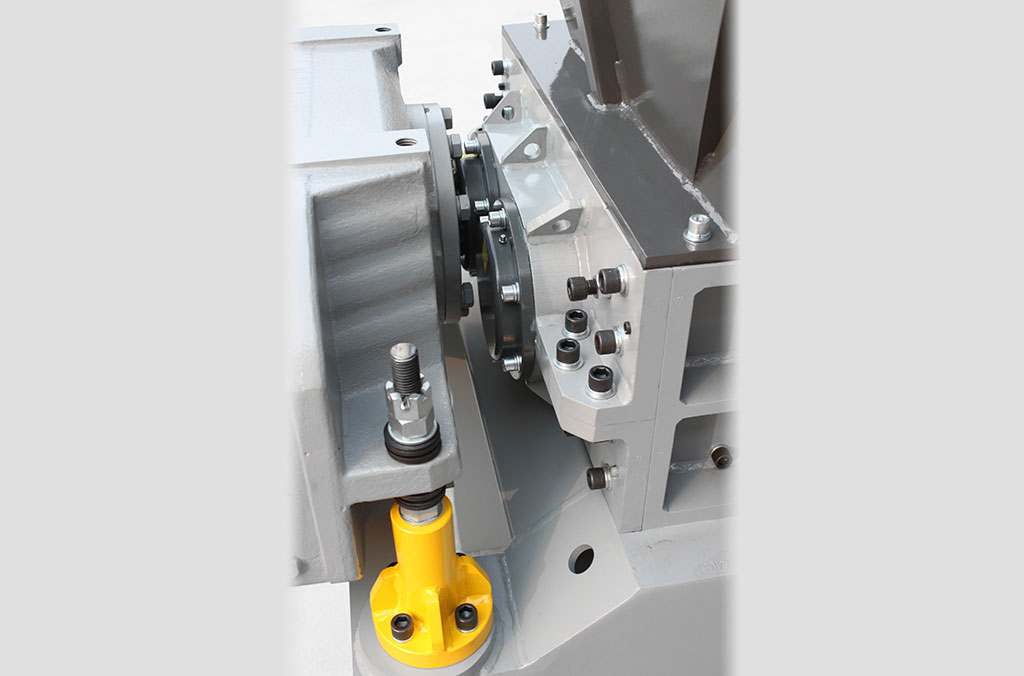

- Rugged Low Maintenance Design.

- Shock Absorbing Gearbox Mounting Arrangement reduces Stress on Drive Components.

- Strong Blades manufactured from high-quality steels are suitable for shredding tough materials.

- Two Piece Split Bearing Housing Arrangement enables quick access to bearings and rotor.

- Advanced Adjustable Sealing System prevents product migration and ensures long bearing service life.

- Stand Alone Electrical Control Panel with Siemens PLC Control System.

- Tested, Approved and Certified to the applicable CE safety standards.

M Series Twin Shaft Shredder

Click the button to the right to request the specifications for this shredder.

Specifications

M SERIES SHREDDER

| MODEL | M400 | M800 | M1200 |

| Dimension (in) | 63 x 48.2 x 72.8 | 106.7 x 50 x 72.8 | 140.9 x 77.4 x 86.6 |

| Hopper Opening (in) | 15.7 x 18.9 | 31.5 x 18.9 | 47.2 x 28.5 |

| Discharge Height (in) | 23.6 | 25.2 | 34.4 |

| Rotation Diameter (in) | Ø 10.9 | Ø 10.9 | Ø 16.9 |

| Rotation Speed (RPM) | 13/7.7 | 14 | 15 |

| Number of Blades (PCS) | 10+10 | 20+20 | 15+15 |

| Blade Width (in) | 0.8 | 0.8 | 1.6 |

| Main Drive (hp) | 10 | 10+10 | 30+30 |

| Hopper Volume(L) | 550 | 750 | 1360 |

| Weight (lbs) ~ Approx | 3241 | 5071 | 11288 |

| MODEL | M400 | M800 | M1200 |

| Dimension (mm) | 1600 x 1225 x 1850 | 2710 x 1270 x 1850 | 3580 x 1965 x 2200 |

| Hopper Opening (mm) | 400 x 480 | 800 x 480 | 1200 x 725 |

| Discharge Height (mm) | 600 | 640 | 875 |

| Rotation Diameter (mm) | Ø 276 | Ø 276 | Ø 430 |

| Rotation Speed (RPM) | 13/7.7 | 14 | 15 |

| Number of Blades (PCS) | 10+10 | 20+20 | 15+15 |

| Blade Width (mm) | 20 | 20 | 40 |

| Main Drive (kw) | 7.5 | 7.5+7.5 | 22+22 |

| Hopper Volume(L) | 550 | 750 | 1360 |

| Weight (kg) ~ Approx | 1470 | 2300 | 5120 |