Maximizing Productivity: The Role of Shredders and Granulators in the Manufacturing Process

Efficiency and productivity are critical for modern manufacturing plants, and optimizing waste management is a key factor. At Genox USA, advanced industrial shredders and granulators play a vital role in transforming waste into valuable resources, reducing disposal costs, and boosting sustainability efforts.

In this blog post, we’ll explore how shredders and granulators enhance productivity by managing waste, streamlining recycling processes, and contributing to a circular economy.

1. Waste Management and Recycling: Core to Manufacturing

Effective waste management is essential for maintaining a clean, organized, and cost-efficient manufacturing environment. Manufacturing plants generate substantial amounts of waste in the form of offcuts, defective products, packaging materials, and byproducts. Without proper waste processing solutions, these materials can take up valuable space, increase disposal costs, and negatively impact the environment.

This is where recycling and recycling technology come into play. Recycling is an integral part of sustainable manufacturing, enabling companies to minimize their environmental footprint while also recovering valuable materials that can be reused in production. By implementing advanced recycling management strategies, manufacturing plants can reduce waste, save costs, and meet environmental regulations.

2. The Role of Industrial Shredders in Productivity

Industrial shredders are highly effective machines that break down large, bulky materials into smaller pieces, making them easier to handle, transport, and recycle. Shredders offer several key benefits that directly impact productivity in manufacturing plants:

- Volume Reduction: Shredders significantly reduce the size of waste materials, such as metal scraps, plastics, wood, and more. This makes it easier to store and transport the waste, freeing up valuable floor space in the plant and reducing transportation costs.

- Enhanced Recycling Efficiency: Shredded materials are easier to process and recycle. By reducing waste into smaller pieces, manufacturers can optimize their recycling processes and ensure that materials are properly separated and prepared for reuse.

- Cost Reduction: By reducing the volume of waste and facilitating easier recycling, industrial shredders help reduce overall waste disposal costs, while also contributing to a cleaner, more efficient production environment.

Genox USA offers a wide range of industrial shredders designed to handle various types of waste, providing manufacturing plants with the tools they need to improve their waste management processes.

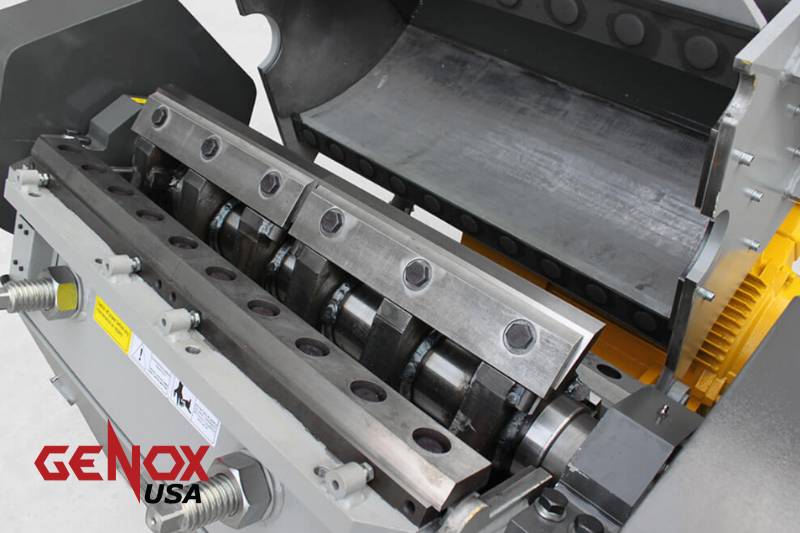

3. How Granulators Enhance the Manufacturing Process

While industrial shredders break down bulky materials, granulators take the process a step further by turning shredded waste into fine granules or small particles. This makes the materials easier to recycle, repurpose, or reintroduce into the production process.

- Material Reuse: Many manufacturing plants generate waste materials, such as plastic or rubber, that can be reprocessed into new products. Industrial granulators reduce these materials into fine granules, which can be melted down and reused, minimizing the need for new raw materials.

- Improved Recycling: Granulated waste is easier to handle and transport, making the recycling process more efficient. Whether it’s plastics, metals, or other materials, granulators help ensure that waste is recycled effectively, reducing the amount of waste sent to landfills.

- Energy Efficiency: Modern granulators are designed to operate efficiently, using less energy while delivering high throughput. This makes them a cost-effective solution for manufacturers looking to streamline their recycling processes.

By incorporating industrial granulators into their waste management strategies, manufacturers can not only reduce waste but also recover valuable resources for reuse, boosting sustainability and lowering costs.

4. Reducing Environmental Impact with Shredders and Granulators

Sustainability is a growing concern for manufacturers, and reducing the environmental impact of production processes is a top priority. By integrating shredders and granulators into the manufacturing process, plants can significantly reduce their waste output and minimize their reliance on raw materials.

- Waste Reduction: Shredders and granulators help manufacturers process and recycle a wide range of materials, including plastics, metals, paper, and more. By reducing waste volume and maximizing recycling, manufacturers can lower their carbon footprint and meet sustainability goals.

- Contributing to the Circular Economy: Shredding and granulating waste materials not only help manufacturers reduce waste but also create a pathway for repurposing these materials in new products. This supports the concept of a circular economy, where waste is minimized, and materials are reused as much as possible.

- Compliance with Regulations: Many industries face strict environmental regulations regarding waste management and recycling. By using advanced recycling technology, manufacturers can ensure that they comply with these regulations while also improving their operational efficiency.

At Genox USA, we offer cutting-edge industrial shredders and granulators designed to help manufacturers minimize their environmental impact and achieve their sustainability goals.

5. Boosting Overall Productivity with Genox USA

Implementing shredders and granulators into your manufacturing operations provides a direct path to enhanced productivity. Here’s how these machines can help:

- Streamlined Operations: By reducing waste volume and facilitating more efficient recycling, shredders and granulators streamline waste management processes, allowing employees to focus on production rather than waste handling.

- Lower Operational Costs: Efficient recycling reduces disposal and transportation costs, while also enabling manufacturers to recover valuable materials for reuse. This leads to lower overall operating expenses and higher profitability.

- Improved Space Utilization: Shredders and granulators reduce the size of waste materials, freeing up valuable space in the manufacturing facility. This allows for better organization, increased production capacity, and improved safety.

By choosing Genox USA for your waste management and recycling technology needs, you can optimize your manufacturing processes, improve sustainability, and boost productivity.

Contact Genox USA to Learn More About Our Line of Size Reduction Equipment

Shredders and granulators are essential tools for maximizing productivity and efficiency in modern manufacturing plants. At Genox USA, we provide high-quality, durable shredders and granulators that are designed to handle a wide range of materials, from plastics to metals and more. By incorporating these machines into your waste management strategy, you can reduce waste, improve recycling, and lower operating costs, all while contributing to a more sustainable manufacturing process.

Contact Genox USA today to learn more about how our advanced recycling solutions can benefit your plant’s operations and help you achieve your sustainability goals.

Contact Genox USA for more information about our line of size reduction equipment